Page 1 of 1

Crosman Challenger

Posted: Mon Apr 23, 2018 2:34 pm

by Trooperjake

One of our shooters air rifle sprung a leak from the air gauge.

Tried a fix with plumbers tape, but was blown out when we tried a refill.

Any ideas before we have to send the rifle back to Crosman?

Anyone else have this problem?!

Re: Crosman Challenger

Posted: Mon Apr 23, 2018 4:39 pm

by TenMetrePeter

Loctite and let it set overnight?? And don't apply it to the threads until it is almost screwed in.

Don't want anthing in the cylinder particularly ptfe tape.

Re: Crosman Challenger

Posted: Mon Apr 23, 2018 8:53 pm

by jhmartin

Ya know .... you are dealing with high pressure air here.

What if that gauge blows out again during a match & hits another competitor on the line?

That is not a deal that you can overcome and our sport does not need that kind of attention.

Send it back to Crosman & let them fix, or more probably replace the parts that are bad....

My >>>guess<<< is that the shooter overfilled the rifle. You do that to a Crosman & you spring leaks or pop the plastic caps off of the gauge ... I see that happen all the time at matches.

Re: Crosman Challenger

Posted: Mon Apr 23, 2018 10:21 pm

by gspell68

When we went to the JROTC All-Service meet in Phoenix in February, my son's school rifle leaked around the gage, too.

(We depressurized them and transported them on the planes with us.)

A guy from another team had a new gage, still in the box.

Teflon taped it, stuck it in and it still leaked.

The whole gage was loose and could be wiggled up and down.

None of the other eight guns would wiggle like that but I assume that's because we'd pressurized those by then and the seals had expanded in the tube to hold them tight.

Realizing how they are built now, I bet you can wiggle the gage while adding pressure and the seals would probably grab.

Might not be a long term fix, though.

Or it may not apply at all since I think our problem was due to depressurizing them, turning them over to TSA/baggage handlers to bang around, AND taking them up to thinner air at 30,000 feet.

All that probably unseated the seals.

Probably slamming 2,000 p.s.i. against the seals all at once probably did not help, either.

Next time we fly by air, the plan is to leave some pressure in them to keep the seals in place and add pressure slowly.

The fix was a complete overhaul by a gunsmith at the JROTC Nationals match at Camp Perry.

Not sure of the details, though.

Re: Crosman Challenger

Posted: Tue Apr 24, 2018 5:03 am

by TenMetrePeter

So if that block sits inside the cylinder to take the gauge it would be difficult to tell if air was bypassing the gauge threads or bypassing the big o-rings and coming out the hole round the gauge threads.

Curious design!!

Re: Crosman Challenger

Posted: Tue Apr 24, 2018 10:58 am

by bandur60

A comment on overfilling ... we haven't done it (YET) but I can see how easily it could happen. Crosman's PCP pistol fills to 200 bar, hopefully the rifles will be updated to similar capability. If they are, I can see a bunch of mix-up situations happening between the old and the new (unless there was a retrofit offered for the older rifles). Someone else has undoubtedly thought of this, maybe there's something I'm missing? Anyone have an answer or comment?

Re: Crosman Challenger

Posted: Tue Apr 24, 2018 12:22 pm

by gspell68

TenMetrePeter wrote:So if that block sits inside the cylinder to take the gauge it would be difficult to tell if air was bypassing the gauge threads or bypassing the big o-rings and coming out the hole round the gauge threads.

Curious design!!

Exactly!

I couldn't wrap my head around it either, especially in the panic of an equipment check by the officials at a national tournament where two of five guns crapped out.

I would've figured that the gauge screwed into a fixed/welded or otherwise permanently capped cylinder.

When I noticed that I could wiggle the gage, I figured something broke loose inside.

It didn't make sense until I found this newer exploded parts diagram.

https://support.crosman.com/hc/en-us/ar ... 0-Present-

I was going off this older exploded view shows the transfer part assembly at the other end of the tube, because the cylinder doesn't quite come apart like this...

https://support.crosman.com/hc/en-us/ar ... -EVP-2009-

We weren't the only ones with issues.

Apparently the Challengers don't travel well by air.

(I got bit before on a trip by broken sear pins, but that was kinda my fault.)

Re: Crosman Challenger

Posted: Wed Apr 25, 2018 3:15 am

by spektr

The comment of the reduction in air pressire due to cruising altitude of the airplane is baseless.... The cargo compartmemts are pressurised to the same altitude as the cabin and it is regulated by the cabin outflow valve. Common practice is to allow the cabin altitude to climb to 8500 feet msl and keep it there. This eliminates the requirement for crew supplemental oxygen beginning at 10k ft msl.......

Re: Crosman Challenger

Posted: Wed Apr 25, 2018 4:44 am

by TenMetrePeter

I prefer the design where gauge is on the end of a removable cylinder where...

1. gauge can sit in an o'ring cavity on a flat face

2. Failing gauge hits the end wall not your neighbor.

These guns are made to a price to fit the sporter rules and it shows.

Re: Crosman Challenger

Posted: Wed Apr 25, 2018 4:10 pm

by gspell68

spektr wrote:The comment of the reduction in air pressure due to cruising altitude of the airplane is baseless.... The cargo compartments are pressurized to the same altitude as the cabin and it is regulated by the cabin outflow valve. Common practice is to allow the cabin altitude to climb to 8500 feet msl and keep it there. This eliminates the requirement for crew supplemental oxygen beginning at 10k ft msl.......

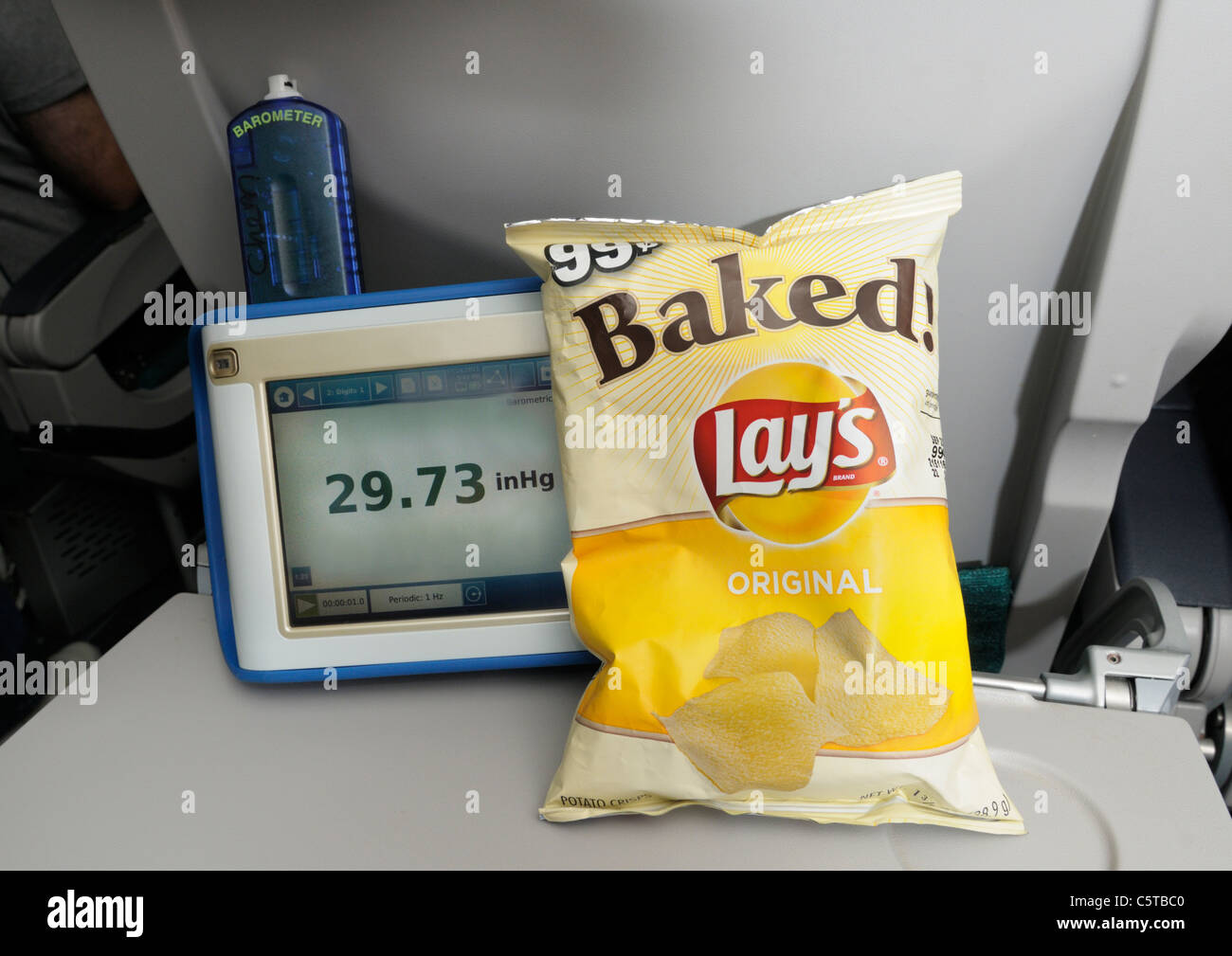

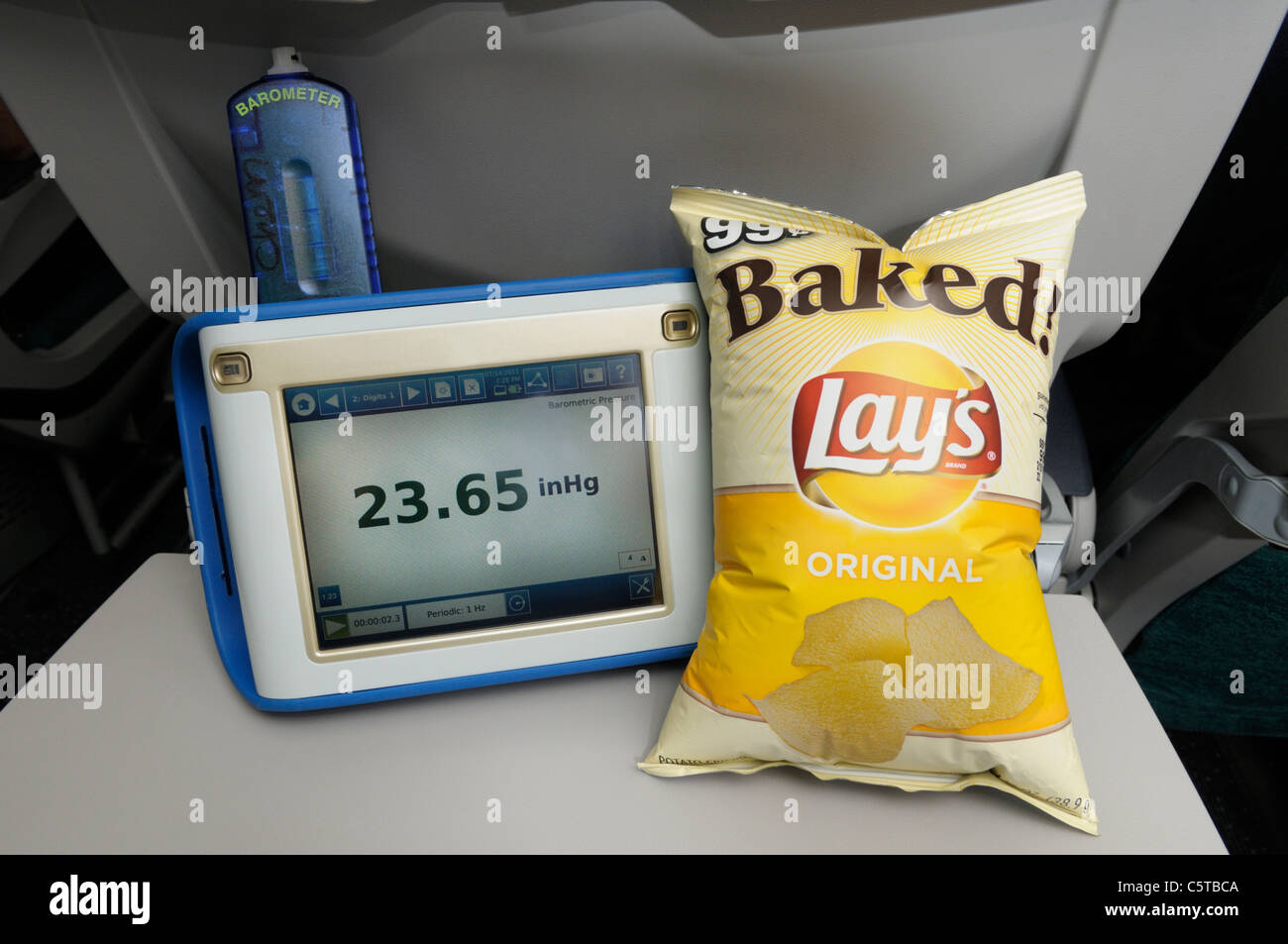

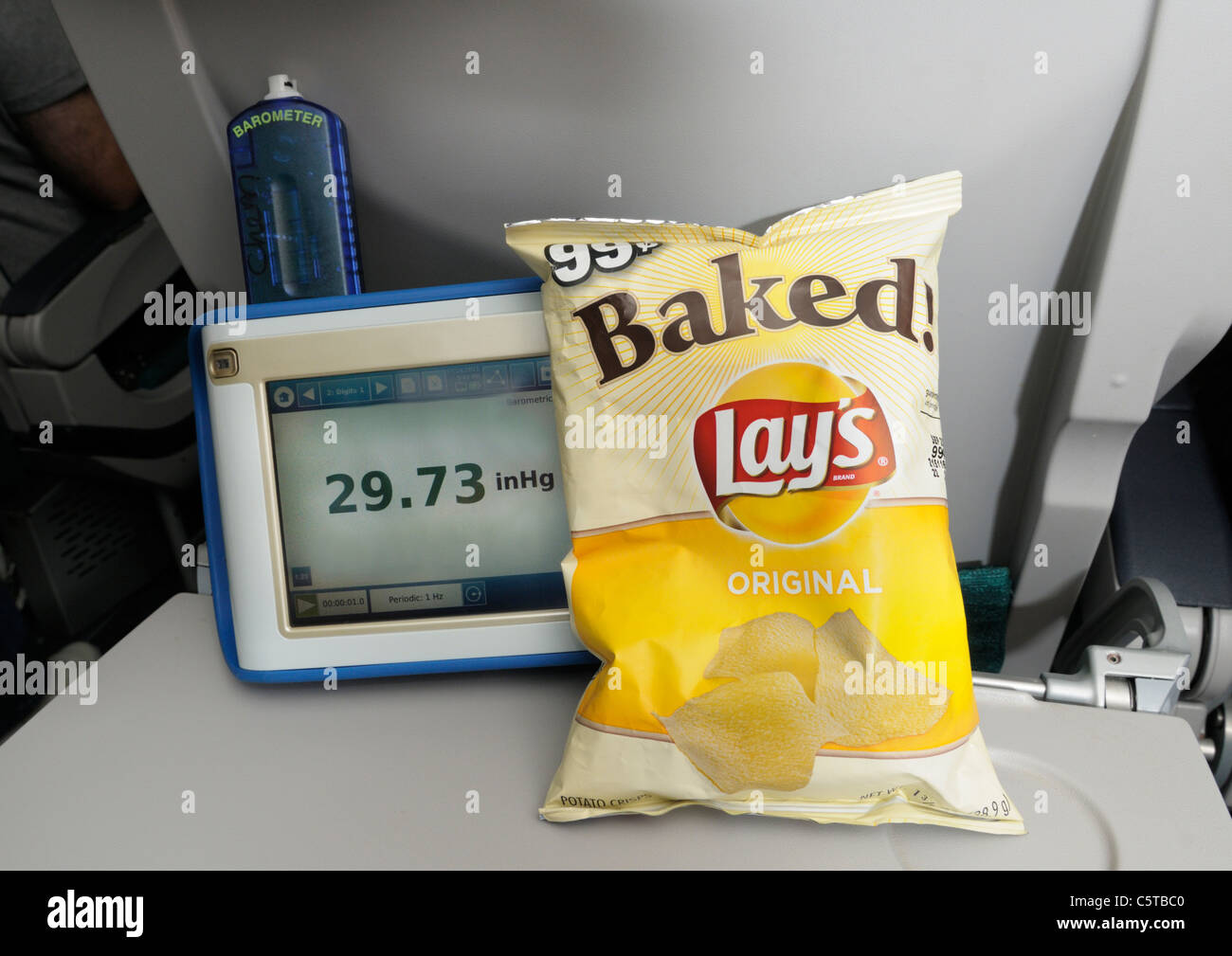

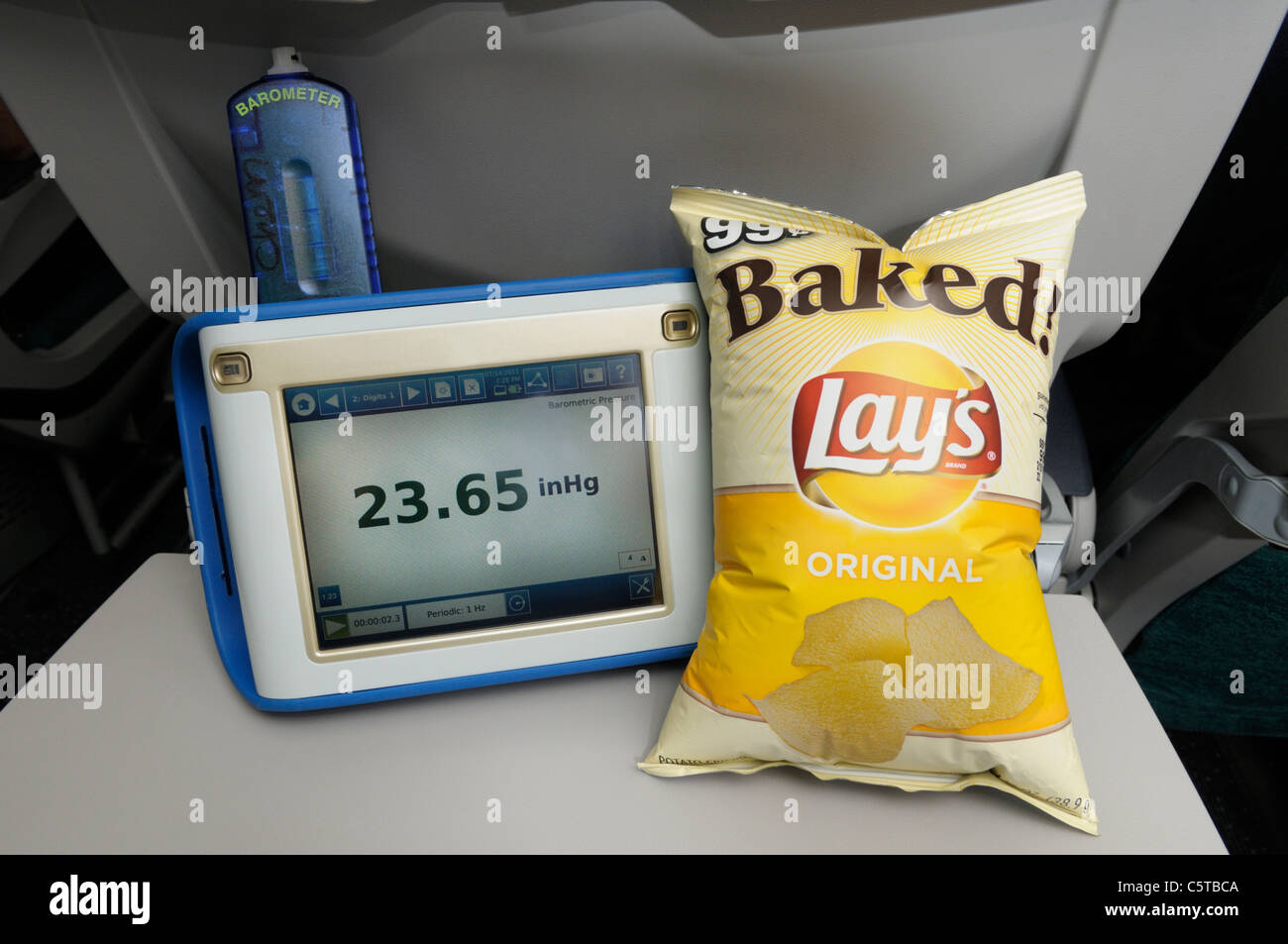

Maybe not as baseless as you think?

Re: Crosman Challenger

Posted: Wed Apr 25, 2018 10:58 pm

by Trooperjake

Thanks for all the replies.

We sent the rifle back to Crosman.

Hope it doesn't take too long to get back.

It was a Crosman Tech that recommended the plumbers tape.

It wasn't the gauge that blew out, it was the plumbers tape.

There are enough treads to prevent the gauge from blowing out.

Re: Crosman Challenger

Posted: Thu Apr 26, 2018 4:58 am

by TenMetrePeter

Unbelievable, but I guess that means it is a taper thread. I still would have used purple Loctite and left it 12 hours. And not eorry if the gauge finishes up not straight.

Re: Crosman Challenger

Posted: Fri Apr 27, 2018 12:50 am

by spektr

23.65 inches of mercury gives you a pressure altitude of 6326 feet. My guess is that might be a 787 cabin reading. They fly at lower cabin altitudes because the carbon fuselages have greater hoop tension strength than metallic structures and the higher Delta P is accounted for in the design. Metallic structures as a rule fly at higher pressure altitudes to reduce hoop tension loads and minimise fatigue of the structures..... Nice picture by the way.....