Page 9 of 13

toz 35

Posted: Tue Feb 08, 2011 1:48 pm

by agentr

David's comment as to POI being lost in wobble within your hold is valid and would hold true for most all shooters just as he stated. I was speaking strictly from a precision point of view ie. firing from a ransom rest where wobble has been eliminated. The guy asked if it could change the point of impact. Answer: Yes! Will it make any difference to him or anyone else? Probably not!

As for whether Neal's weight came with the gun or not...he told me in January of this year that he "had one made" for his Toz and suggested I do the same. In the same sentence, he mentioned the bit about barrel harmonics. In the end, whether the pistol came with the weight or was added later, is really just splittin' hairs...isn't it?

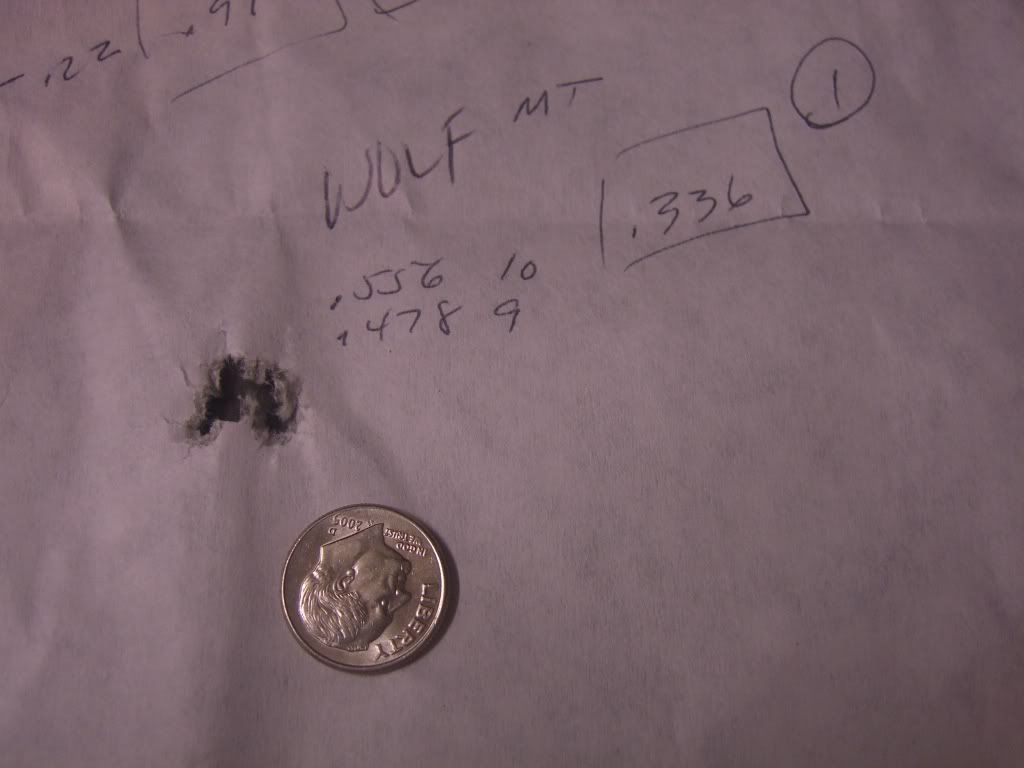

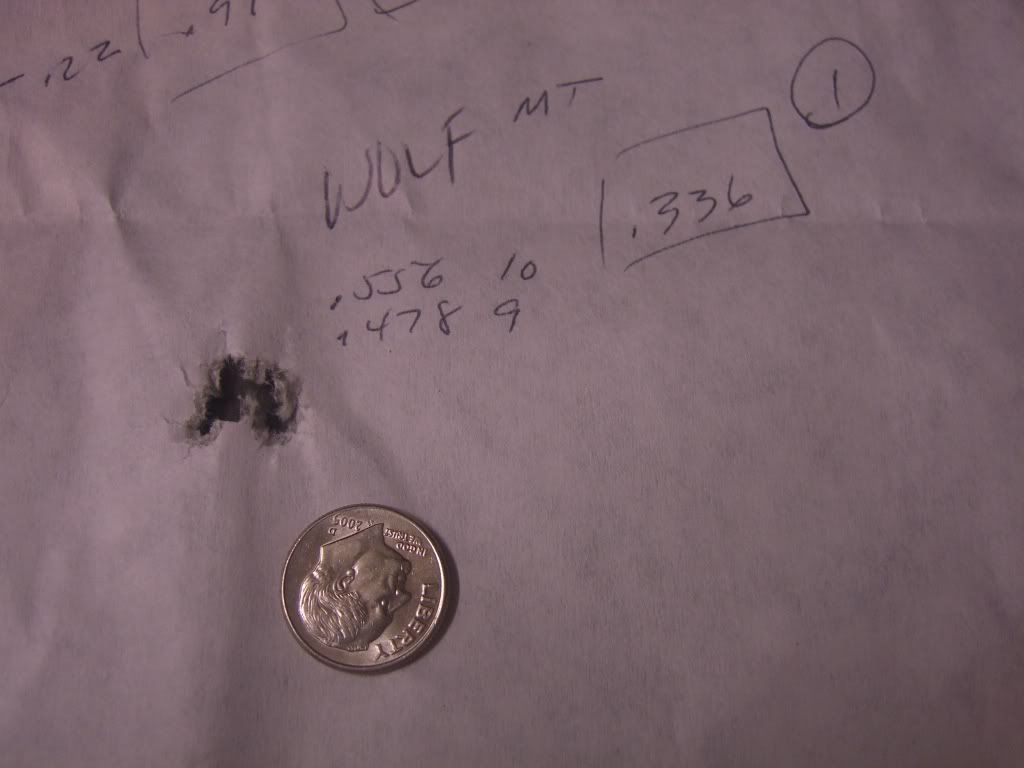

Incidentally my Toz, after I finished refurbishng it, shoots 10 shot groups down to .336" from a rest at 50M . I'll never shoot it that well, but...that also is "incidental"! ;^)

Reid

toz 35

Posted: Mon Oct 03, 2011 4:17 pm

by agentr

This mod removed 35-40 grams from total weight of my toz 35. (the drill shavings ended up all over my shop making it difficult to determine exact weight reduction) I'll clean up the rough edges later and will probably remove less than one gram

Posted: Mon Oct 03, 2011 8:07 pm

by chuckjordan

Can anybody provide some tips in removing the barrel from the TOZ (35 not 35M). Why? It needs a new crown and attached to the frame it won't fit in the 4-jaw chuck...

I know unscrew it, but, is it pinned in (I didn't see any) or does it have LH or RH threads?

Thanks

Chuck

removing TOZ 35 barrel

Posted: Mon Oct 03, 2011 10:43 pm

by BEA

No pins holding it in, right hand thread. Remove the extractor. You need to put the barrel in a barrel vise with the properly sized bushing for the diameter. Turn the action with a crescent wrench. HOWEVER...you should put a block of steel of the proper width in-between the two thin parts of the frame to keep from bending them. Pad the frame with some brass shim to keep the wrench from scratching it. Note the index mark on the bottom of the barrel so that you can get it back to the same point. It should screw right out.

toz 35

Posted: Tue Oct 04, 2011 1:11 am

by agentr

I recrowned my 35 with the barrel in place. Buy (from Brownells) or rent (from 4-d reamers) an 11* crowning tool with the proper bushing and you'll be done in 5 min!

Posted: Tue Oct 04, 2011 9:10 am

by Freepistol

crowning

Posted: Tue Oct 04, 2011 10:14 pm

by BEA

That might be okay for an old 22 rifle, but where accuracy is paramount such as with a FP, that method is not preferred.

Posted: Wed Oct 05, 2011 8:41 am

by Greg Derr

I agree with BEA, the barrel should be turned in a lathe to insure concentricity to the bore for the new crown, not an easy task. Since the barrel is recessed from the front of the sight mount, you could even go with no crown like the Hammerli 208 for example.

Posted: Wed Oct 05, 2011 4:09 pm

by zoned

Greg Derr wrote:... the barrel should be turned in a lathe to insure concentricity to the bore for the new crown....

Ideally, lathe turning a barrel is the proper procedure to re-crown a muzzle. As mentioned previously, there is another way to obtain a precision result as the illustrations show....

http://tinyurl.com/43xygjs

It takes longer than 5 minutes, though.

Re: toz 35

Posted: Thu Oct 06, 2011 12:20 am

by agentr

agentr wrote:I recrowned my 35 with the barrel in place. Buy (from Brownells) or rent (from 4-d reamers) an 11* crowning tool with the proper bushing and you'll be done in 5 min!

Again!

Posted: Thu Oct 06, 2011 9:10 pm

by chuckjordan

Thanks all! I see the alignment marks.

I have a friend with a 4-jaw chuck and he's crowned airgun bbls, also my Marlin 39a. Centers from the bore and has a special bit. It takes about 15 minutes to center the bore, and 1-2 to cut the crown.

I know the muzzle is recessed (protected). I'd like to do it flat like the factory.

My gunsmith has the 11' tool which I'll use as a last resort.

I'd like to get it right so I don't beat myself up later when I miss (I won't be able to blame the TOZ then).

Question: 11' crown or 0' ?? (in the 4-jaw chuck, of course) ?? The factory crown looks to be 0'

That's why I like this forum, so many helpful people.

Manson crowning tool

Posted: Fri Oct 07, 2011 11:40 am

by Dr. Jim

To add to your options. I purchased one of Dave Manson's Crowning tools and 5 pilots. I redid a number of crowns on match guns that had been crowned with my Brownell's tool. The process is simplicity itself and in about 5 minutes per barrel cuts a perfect 11 degree crown. Only failure was trying it on a pair of old Norinco 9mm barrels that turn out to be machined and then HARD CHROMED. All the carbide cutter could do with the hand force applied is polish the surface. True, the tool is considerably more expensive than the Brownell tool, but IMHO it is far superior and unlike the lathe, does not require any disassembly.

Dr Jim

toz 35

Posted: Fri Oct 07, 2011 1:06 pm

by agentr

I went with the 11*. There is no protection for a flush cut crown. The reason I went with a crown cutter and not a lathe is that it VERY difficult to ensure your new crown will be perpendicular to the bore UNLESS you use the crown cutter. Furthermore, if you don't have a 35M, the front sight shroud is a pressed fit, and will be difficult to re-align if removed. The 11* cutter, cuts just inside the shroud, so you can cut it in place. This crown achieves groups under .34" at 50 meters. Your choice?

[/img]

Re: toz 35

Posted: Fri Oct 07, 2011 2:03 pm

by j-team

agentr wrote:I went with the 11*... This crown achieves groups under .34" at 50 meters.

Well you can't argue with that result.

What kind of groups did you get before the recrown?

And, was poor grouping the reason you recrowned it in the first place?

Posted: Sat Oct 08, 2011 1:09 am

by LukeP

.34" groups are outstanding! is like 8mm at 50 meters, really?

Good job!

toz 35

Posted: Mon Oct 10, 2011 12:08 am

by agentr

The crown , before the re-crown, had a visible gnash in it. I did not Ransom Rest the pistol like I did after the recrown. Testing had been done off sandbags achieving 1.5-3" groups. This could not be considerd a fair comparison because Ransom Rest testing is so much more reliable than a sand bag. I merely wanted to point out that you don't HAVE to use a lathe to get a good result when re-crowning a barrel.

NOTE: That's ten shots NOT just five. (.556"-22cal=.336" is best of several attempts but all were under .8" depending on the ammo used)

toz 35

Posted: Wed Oct 12, 2011 10:19 pm

by agentr

Total Strip of Trigger Unit

Posted: Mon Oct 24, 2011 7:08 am

by chuckjordan

I've stripped apart most of my TOZ-35, it's going in for a reblue. All except for the sear parts in the trigger unit.

The trigger unit has two .040" pins holding sear parts. And I don't have a drift punch that thin. I've used brad nails thin enough, but, they don't have the strength and bend as these pins are 'pinned' in rather tight.

Suggestions? I'd rather not reblue the trigger unit with the sear parts as 1-2 parts appear to be stainless?

Pics of trigger unit below:

My last option is to strip only the rust off (bead-blast it) and then use Dicropan for a chem. blue. Not as good as a caustic bluing/blackening.

Toz 35

Posted: Mon Oct 24, 2011 11:58 am

by agentr

Go to a machine supply shop. They will have the proper punch and Lowes might as well ($4-8). Make sure you are drifting from the left side of the frame (left side while looking down the sights). Your pins appear to be staked from the right (mushroomed on the right side) but double check and drift from the non-mushroomed side. Make sure the pistol frame is mounted securely in a vise as close to the pins as possible, and still allow access, or the proper force is difficult to deliver to the pin. Hopes this helps

Posted: Mon Oct 24, 2011 6:57 pm

by chuckjordan

Yes, that helps. Never thought of a machine shop!

Also thanks for the other help that you've provided! It is appreciated.

[/img]

[/img]