Pardini HP 32, ammo talk

Moderators: pilkguns, m1963, Isabel1130

Re: Pardini HP 32, ammo talk

Pure speculation here on Zipp0's experience....

The one thing that struck me as odd was the practice of resizing a loaded round. Did I understand that correctly..... That you crimped a round and, for some reason, resized it?

If so, it is quite possible that the case sprung back a bit, but the bullet itself was slightly swaged down to a smaller diameter. You would have lost your case neck tension on the bullet. But, the crimp might have still held it well enough to feed. The ignition of the primer easily drove the bullet before the powder could ignite. (Smokeless powder is a progressive burning substance that will not combust without sufficient chamber pressure.)

Under the same circumstances, a magnum primer would have simply driven the bullet further down the bore.

For the tiny case capacity, a standard primer is all that's needed.

At least that's my conjecture, for what it's worth.

Best Regards,

Jim

The one thing that struck me as odd was the practice of resizing a loaded round. Did I understand that correctly..... That you crimped a round and, for some reason, resized it?

If so, it is quite possible that the case sprung back a bit, but the bullet itself was slightly swaged down to a smaller diameter. You would have lost your case neck tension on the bullet. But, the crimp might have still held it well enough to feed. The ignition of the primer easily drove the bullet before the powder could ignite. (Smokeless powder is a progressive burning substance that will not combust without sufficient chamber pressure.)

Under the same circumstances, a magnum primer would have simply driven the bullet further down the bore.

For the tiny case capacity, a standard primer is all that's needed.

At least that's my conjecture, for what it's worth.

Best Regards,

Jim

Re: Pardini HP 32, ammo talk

An insightful post 6string and I too, am thinking about how a lack of pressure could have caused the problem, however, the failure was when I was using the 'PRO' dieset from Redding which does not need the resizing after the dedicated crimp die. It was the seat / crimp die of the original Redding dieset I received from Dillon that necessitated the resize. It would not have chambered if it had not been crimped so I am still scratching my head a bit.....

Worth mentioning that I have found the 32acp gauge from uniquetek to be very useful (certainly in the initial stages of the process).

Worth mentioning that I have found the 32acp gauge from uniquetek to be very useful (certainly in the initial stages of the process).

-

j danielsson

- Posts: 161

- Joined: Mon Sep 16, 2013 6:31 am

Re: Pardini HP 32, ammo talk

I have sized loaded cartridges in 32 s&w l.

With and without crimp. The reason was to get a

309 bullet in a 308 barrel. No problem.

Loose bullets, yes, but no problem.

About mag primers, my experience is, again I'm talking

32 s&w l, they do push the bullet further than std

primers do. Hence you get a bigger chamber before

powder starts to build pressure. Less recoil, less

muzzlejump and less speed occurs. No problem.

None of the above can be reasons for squibs.

With and without crimp. The reason was to get a

309 bullet in a 308 barrel. No problem.

Loose bullets, yes, but no problem.

About mag primers, my experience is, again I'm talking

32 s&w l, they do push the bullet further than std

primers do. Hence you get a bigger chamber before

powder starts to build pressure. Less recoil, less

muzzlejump and less speed occurs. No problem.

None of the above can be reasons for squibs.

-

shootaholic

- Posts: 26

- Joined: Mon Apr 20, 2015 6:46 pm

- Location: West Australia

Re: Pardini HP 32, ammo talk

Hi Zip,

your post regards your Dad's muzzle loader was very interesting, it would be good to see a Digi pic of it.

I have a FWB History #1 which I use in the Aussie 50m BP match. It's a 40 shot [4 x 10 shot series] on the Mayleigh Cup target. I think the National record is 480.

After each shot I use a nylon brush with a very light spray of Windex [ a common glass cleaner] , every one uses it as it easily dissolves black powder residue.

After throwing the powder charge, I throw a similar amount of Polenta, then the patched ball or my swaged .371 HBWC. The polenta stops a damp or wet patch from contaminating the powder.

The FWB will easily hold the x ring when tested with a scope.

I bet you claimed the Yorker through the 10 ring!

Regards

Max

your post regards your Dad's muzzle loader was very interesting, it would be good to see a Digi pic of it.

I have a FWB History #1 which I use in the Aussie 50m BP match. It's a 40 shot [4 x 10 shot series] on the Mayleigh Cup target. I think the National record is 480.

After each shot I use a nylon brush with a very light spray of Windex [ a common glass cleaner] , every one uses it as it easily dissolves black powder residue.

After throwing the powder charge, I throw a similar amount of Polenta, then the patched ball or my swaged .371 HBWC. The polenta stops a damp or wet patch from contaminating the powder.

The FWB will easily hold the x ring when tested with a scope.

I bet you claimed the Yorker through the 10 ring!

Regards

Max

Re: Pardini HP 32, ammo talk

Dipnet,

I've been reading this post again and I have a couple of questions for you (and everyone else...)

On page 14 of this tread you have these two sentences that I would like to ask more about,

By the way, this is probably one of the best topics on TT!

The only one that comes to mind that is equally good is the one on modifying a TOZ free pistol.

Thanks to all, I've learned a lot from this!

I've been reading this post again and I have a couple of questions for you (and everyone else...)

On page 14 of this tread you have these two sentences that I would like to ask more about,

Can you post a picture of this... I'm looking for a cheaper alternative to a ranson rest to test some .32 S&W LongDipnet wrote: My very carefully fired shots off my home made rest (a modified HySkore Parallax Pistol Vise Shooting Rest) nearly equal ransom accuracy at 25 yards (had to replicate at 50 though).

Do you notice any diference if you do not sort the bullets? I understand the need for uniformity, just want to know how much diference does it make.Dipnet wrote:Powder weights are checked using an analytic balance (+ or - 0.02gr accuracy), and bullets are sorted into 0.3gr lots (e.g., 61.7-62.0, 62.1-62.4, & 62.5-62.8 covers about 90% of Travis' bullets).

By the way, this is probably one of the best topics on TT!

The only one that comes to mind that is equally good is the one on modifying a TOZ free pistol.

Thanks to all, I've learned a lot from this!

Re: Pardini HP 32, ammo talk

I just use a sandbag front and back with an 8 power scope. You could probably use a rifle scope if it wouldn't bump the barrel . The gun doesn't kick that hard so it won't hit you in the face. If you do this, put some duct tape on the bottom of the scope where it goes in front of the barrel or it will smear junk all over it. For the Pardini 32 ACP I do everything with the scope because I didn't care much for the way it attached to the RR. I don't think there is a block for my Benelli 32 long. I would rather use my RR if it works well because it is so much faster and doesn't require the same level of concentration. It is hard to fire a lot of shots off a sandbag without wearing yourself out.

Re: Pardini HP 32, ammo talk

in answer to the .3gr cohort question..... (before I shell out for a dopplar chrono...)

I ran up a spreadsheet to calculate the theoretical muzzle velocity changes if the mass of the bullet changes .3gr from the base load - I assumed Ek (Kintetic energy .5M* V2) is constant (I Used Kg for Mass and ms-1 for V to give energy in Joules) and then knowing the energy (32acp 1.6 gr VV130 and 62gr bullet is at 850fs-1 is about 134 J I could calc the Velocity: (SQRT (134/.5M)). Not a lot: 1.6fs-1 - I then calced transit time based on MV and the drop (0.5g*T2) ITOO - -.7mm over 0.3gr (but I did not decay the velocity on the trip to the target). (The doppler radar gives the transit time)

The reason I did it was to look at the order of magnitude of the variances - the answer - not a lot (theoretically) but as I am basically an empirical type - time to test. The difference is an empirical guy has an easier time: how fast does a car go? - the theoretical guy calcs the power, gear ratios, transmission loss, wind resistance etc etc - I (on the other hand) need a straight road and 'give 'er'.....

PM me for the SS if you are interested: You can look at the difference between any velocity and mass ie 45acp 200gr vs 180gr to see the difference

~zip

I ran up a spreadsheet to calculate the theoretical muzzle velocity changes if the mass of the bullet changes .3gr from the base load - I assumed Ek (Kintetic energy .5M* V2) is constant (I Used Kg for Mass and ms-1 for V to give energy in Joules) and then knowing the energy (32acp 1.6 gr VV130 and 62gr bullet is at 850fs-1 is about 134 J I could calc the Velocity: (SQRT (134/.5M)). Not a lot: 1.6fs-1 - I then calced transit time based on MV and the drop (0.5g*T2) ITOO - -.7mm over 0.3gr (but I did not decay the velocity on the trip to the target). (The doppler radar gives the transit time)

The reason I did it was to look at the order of magnitude of the variances - the answer - not a lot (theoretically) but as I am basically an empirical type - time to test. The difference is an empirical guy has an easier time: how fast does a car go? - the theoretical guy calcs the power, gear ratios, transmission loss, wind resistance etc etc - I (on the other hand) need a straight road and 'give 'er'.....

PM me for the SS if you are interested: You can look at the difference between any velocity and mass ie 45acp 200gr vs 180gr to see the difference

~zip

Last edited by Zipp0 on Sat Jan 14, 2017 11:05 am, edited 1 time in total.

-

shootaholic

- Posts: 26

- Joined: Mon Apr 20, 2015 6:46 pm

- Location: West Australia

Re: Pardini HP 32, ammo talk

Bugger me Zippo, that has given me a migrane.

Re: Pardini HP 32, ammo talk

Your math is good and so would be a Doppler chrono but what worries me is that neither method displays where the weight gain or loss comes from but assumes that it is even all over the bullet which may or may not be true.

When casting my own bullets I have learned that the faster the lead gushes into the mold, the better the fillout. However whenever casting from a bottom pour pot, the faster you pour into the mold the more likely you are to get particles that over time gather on the hole through the pot, break loose and get into the quickly swirling travel of the alloy wherein the dirt gets trapped somewhere inside the bullet.

When pouring slowly it gives a less perfect bullet but the dirt which is the same has a tendency to go into the sprue or at least to the back of the bullet if your speed is better but not perfect where you can see it on the base.

This is why pouring with a ladle works so well. When one is constantly whacking the ladle on the side of the pot to knock off the dirt it doesn't have as much chance to deposit any into the bullet. I use this method when casting BPCR bullets but since they weigh around 400 grains and are shot at 550 yards it is even more important. I weigh each of them and put them in categories where I only use the ones which are the majority in the middle.

For the little 32 bullets this would be very tedious. What I do is pressure pour with the spout on the bottom pour pot tight to the mold and I make the lead come out of the pot as slowly as is practical. I always look at the pour without the mold in place and I want smooth lead flow to turn into drips around an inch from the spout. If I am pouring a 200 grain 45 bullet I count to three and then move the mold. With the 32 it is less but I count to two. If I get the pour too fast I start to see dirt in the back of the bullet at which time I am worried some might be in the bullet so I slow it down.

The problem doing this is that unless your column height of the lead in the pot stays very close to the same, (around one inch variation) the pour velocity will get too slow quickly. To counter this I have a Waage pot with melted lead sitting next to my bottom pour pot and around every two pounds of bullets I pour two pounds of alloy back into my casting pot so the temperature doesn't vary. Dropping two pounds of cold lead in will make the temperature vary too much. It varies with the size bullet you are molding but I usually have the depth in the pour pot around 2-3 inches

If you don't cast for yourself and use bullets cast on a machine, they will not be pressure poured so you are at the mercy of whatever you get and I would expect they do it as fast as they can where the bullets still look good. You are also stuck with the alloy that they choose. The harder the bullet the easier it is to cast but that doesn't necessarily mean they will be the most accurate.

When casting my own bullets I have learned that the faster the lead gushes into the mold, the better the fillout. However whenever casting from a bottom pour pot, the faster you pour into the mold the more likely you are to get particles that over time gather on the hole through the pot, break loose and get into the quickly swirling travel of the alloy wherein the dirt gets trapped somewhere inside the bullet.

When pouring slowly it gives a less perfect bullet but the dirt which is the same has a tendency to go into the sprue or at least to the back of the bullet if your speed is better but not perfect where you can see it on the base.

This is why pouring with a ladle works so well. When one is constantly whacking the ladle on the side of the pot to knock off the dirt it doesn't have as much chance to deposit any into the bullet. I use this method when casting BPCR bullets but since they weigh around 400 grains and are shot at 550 yards it is even more important. I weigh each of them and put them in categories where I only use the ones which are the majority in the middle.

For the little 32 bullets this would be very tedious. What I do is pressure pour with the spout on the bottom pour pot tight to the mold and I make the lead come out of the pot as slowly as is practical. I always look at the pour without the mold in place and I want smooth lead flow to turn into drips around an inch from the spout. If I am pouring a 200 grain 45 bullet I count to three and then move the mold. With the 32 it is less but I count to two. If I get the pour too fast I start to see dirt in the back of the bullet at which time I am worried some might be in the bullet so I slow it down.

The problem doing this is that unless your column height of the lead in the pot stays very close to the same, (around one inch variation) the pour velocity will get too slow quickly. To counter this I have a Waage pot with melted lead sitting next to my bottom pour pot and around every two pounds of bullets I pour two pounds of alloy back into my casting pot so the temperature doesn't vary. Dropping two pounds of cold lead in will make the temperature vary too much. It varies with the size bullet you are molding but I usually have the depth in the pour pot around 2-3 inches

If you don't cast for yourself and use bullets cast on a machine, they will not be pressure poured so you are at the mercy of whatever you get and I would expect they do it as fast as they can where the bullets still look good. You are also stuck with the alloy that they choose. The harder the bullet the easier it is to cast but that doesn't necessarily mean they will be the most accurate.

Re: Pardini HP 32, ammo talk

I have weighed TB Bullets (the dipnet technique).

Oldcaster - how do you factor in the lubricant weight? The 62gr TB bullet has 0.2gr lube in the groove (approx)

Oldcaster - how do you factor in the lubricant weight? The 62gr TB bullet has 0.2gr lube in the groove (approx)

Re: Pardini HP 32, ammo talk

I of course weigh them initially without lube and after they are lubed, who knows how much lube is left on the bullet the instant it leaves the barrel. With hard lube it is common to see all the lube still left but no guarantee. If the lube is real soft it all spins off the moment it leaves the barrel. The downside of soft lube is that it is messy and easy to get on the back of the bullet where it can change the powder charge with a few tenths of a grain sticking to it plus it makes the gun dirtier faster. This is one of D if you do and D if you don't situations and you have to compromise somewhere. I would be happy if the lube was something like Vaseline but it would take 10 minutes to load each bullet correctly.

-

shootaholic

- Posts: 26

- Joined: Mon Apr 20, 2015 6:46 pm

- Location: West Australia

Re: Pardini HP 32, ammo talk

Oldcaster is on the money, the Linotype printing machines of the past had two lead pots, one that poured to make the print slugs and the other was positioned above to automatically top up the bottom pot to maintain the operating level of molten lead and therefore the same pour pressure. This ensured clean sharp print.

Re: Pardini HP 32, ammo talk

The big trick is to figure out how high your lead column should be along with what alloy and what temperature and somewhat how fast you go so your mold stays the temperature throughout your casting session. All of this to a particular mold because they vary especially between size and quality.

A lot of molds are so junky that they can't be pressure poured and some of the old H&G molds are designed so they can't be because of their sprue plate. However a junky mold with a properly designed bullet can be better than a quality mold of something that just isn't the right shape. A good example for me is the Saeco 130 185 grain 45 mold. None of my friends or I can get these to shoot but the mold sure casts well.

A lot of molds are so junky that they can't be pressure poured and some of the old H&G molds are designed so they can't be because of their sprue plate. However a junky mold with a properly designed bullet can be better than a quality mold of something that just isn't the right shape. A good example for me is the Saeco 130 185 grain 45 mold. None of my friends or I can get these to shoot but the mold sure casts well.

Re: Pardini HP 32, ammo talk

I'm also curious about your device. A regular HySkore Parallax Pistol Vise Shooting Rest allows you to stabilize your gun only, more or less like a sandbag. It's not a Ransom Rest though, you still need to re-aim your gun somehow. A scope comes in handy, the only trick is how to mount it. I use a "regular" .32S&W Pardini HP - it is easy to install a picatinny rail on top of it.rmca wrote:Can you post a picture of this... I'm looking for a cheaper alternative to a ranson rest to test some .32 S&W LongDipnet wrote:My very carefully fired shots off my home made rest (a modified HySkore Parallax Pistol Vise Shooting Rest) nearly equal ransom accuracy at 25 yards (had to replicate at 50 though).

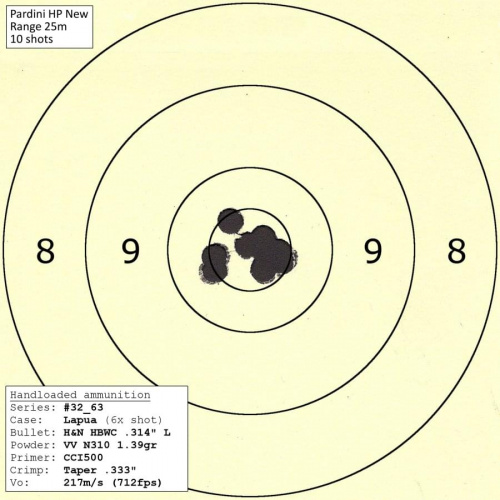

I can't tell for .32ACP, I load .32S&W Long. Though I'm pretty much obsessed with the consistency of my powder charges (1.38-1.40gr), on the other hand I use plain commercial bullets (H&N 100gr). Since they are heavily lubed it is hard to tell their real net weight and it is pointless to sort them. At first I was eliminating even slightly nicked bullets, but then I realized it wasn't necessary. Now I just pick bullets right from the box and voila. I'm satisfied with results, as seen below.rmca wrote:Do you notice any diference if you do not sort the bullets? I understand the need for uniformity, just want to know how much diference does it make.Dipnet wrote:Powder weights are checked using an analytic balance (+ or - 0.02gr accuracy), and bullets are sorted into 0.3gr lots (e.g., 61.7-62.0, 62.1-62.4, & 62.5-62.8 covers about 90% of Travis' bullets).

And for comparison, a factory Lapua 98gr

Re: Pardini HP 32, ammo talk

RCMA,

My thinking on reloading the 32 ACP for target accuracy stems the small ranges in the load variables that affect accuracy, e.g., powder weights only range 1.2 to 2.0 grs; hence, I opine that small variations in any variable could have significant group size effects. I've thought about setting up a BAA (big ass ANOVA) to estimate the contributions of each variable to accuracy, and analyze post hoc interactions, but I am retired, and this is supposed to be fun. A measure of consistency, which is certainly important in hand loading, are the standard deviations of my loads, always less than 10 and usually 4 to 6.

I have a Ransom Rest, which I occasionally set up, but it is a pain in the butt, especially because I don't have the way too-expensive windage adjustment attachment. Also, this tool requires a certain finesse to obtain consistent results (namely following the directions on the mounting the rest and great care in consistently repeating all the little steps involved in setting it up and firing the weapon). I just may sell the darn thing to increase my shooting joy.

Using a modified Hi-Skor rest, I can get consistent results at 25 yards, which are generally (but not always) predictive of results at 50 yards (e.g., the case of the 32 S&W L in a GSP). So, no, I don't have empirical proof that the extra care makes a big difference. Since the first thing the Army Marksmanship Unit teaches is that before anything else, make sure your equipment is in order. That way, when something is off, it is me, not the gun or sight or ammo, but something I'm doing wrong.

Participating is a sport that requires such high focus, technique, and consistency is challenging and sometimes so very aggravating. How many times have you shot a 50 or even 5X with the first magazine on the long line only to blow it with the next five shots? Or shoot a 96 and then an 82! Like fly fishing for wary trout, bullseye shooting has me quietly cursing immediately after a match but on the way home I find myself analyzing errors and planning some more range time to correct mistakes. I wish I had started this in my 20s instead of my 60s, but on the other hand, I'm alive, have a darn nice pistol, and a great weather to shoot in. That is is the most important variable. Best, dipnet

My thinking on reloading the 32 ACP for target accuracy stems the small ranges in the load variables that affect accuracy, e.g., powder weights only range 1.2 to 2.0 grs; hence, I opine that small variations in any variable could have significant group size effects. I've thought about setting up a BAA (big ass ANOVA) to estimate the contributions of each variable to accuracy, and analyze post hoc interactions, but I am retired, and this is supposed to be fun. A measure of consistency, which is certainly important in hand loading, are the standard deviations of my loads, always less than 10 and usually 4 to 6.

I have a Ransom Rest, which I occasionally set up, but it is a pain in the butt, especially because I don't have the way too-expensive windage adjustment attachment. Also, this tool requires a certain finesse to obtain consistent results (namely following the directions on the mounting the rest and great care in consistently repeating all the little steps involved in setting it up and firing the weapon). I just may sell the darn thing to increase my shooting joy.

Using a modified Hi-Skor rest, I can get consistent results at 25 yards, which are generally (but not always) predictive of results at 50 yards (e.g., the case of the 32 S&W L in a GSP). So, no, I don't have empirical proof that the extra care makes a big difference. Since the first thing the Army Marksmanship Unit teaches is that before anything else, make sure your equipment is in order. That way, when something is off, it is me, not the gun or sight or ammo, but something I'm doing wrong.

Participating is a sport that requires such high focus, technique, and consistency is challenging and sometimes so very aggravating. How many times have you shot a 50 or even 5X with the first magazine on the long line only to blow it with the next five shots? Or shoot a 96 and then an 82! Like fly fishing for wary trout, bullseye shooting has me quietly cursing immediately after a match but on the way home I find myself analyzing errors and planning some more range time to correct mistakes. I wish I had started this in my 20s instead of my 60s, but on the other hand, I'm alive, have a darn nice pistol, and a great weather to shoot in. That is is the most important variable. Best, dipnet

Re: Pardini HP 32, ammo talk

Quick question.. Anyone having extraction problems with the 32acp? I switched the extractor in case it was chipped (but the replacement wasn't new). At 850fpsI do not get consistent extraction, with commercial ammo I do. Also, has anyone modified the recoil spring (ie shortened it to accommodate?)

Thanks

~Zip

Thanks

~Zip

Re: Pardini HP 32, ammo talk

Most of us have changed the magazine and recoil spring to the 22 version. I use my 32 magazine spring but I cut off two coils. Also read back and you will find that the magazine lips need to be bent in. A 9/32 drill bit is put in where the bullet fits and then the rear lips are tapped to it. This is just from memory so check what we actually did.

Re: Pardini HP 32, ammo talk

Thanks OC,

I am iterating my way through this. The Labradar chrono seems to be working very well (and v. easy to set up) Just plop it on the bench, switch on, select a new series and away you go (and all data stored on a file (with splits at your selected distances).

I will dig out a 22 spring.

I am iterating my way through this. The Labradar chrono seems to be working very well (and v. easy to set up) Just plop it on the bench, switch on, select a new series and away you go (and all data stored on a file (with splits at your selected distances).

I will dig out a 22 spring.

Re: Pardini HP 32, ammo talk

.22 mag spring cured the problem over 20-30 rounds. Although one mag jammed a bit - so will stiffen the spring...

Last edited by Zipp0 on Wed Feb 01, 2017 1:10 pm, edited 1 time in total.

-

kubikula78

- Posts: 30

- Joined: Wed Jul 27, 2016 6:40 am

Re: Pardini HP 32, ammo talk

Gentlemen,

somewhere here on this forum I read about expander plug. I let make one, with diameter .313 and lenth of the plug is set to calibrate inside of the case to same distance where bullet goes. I am using .314 HN wadcutters. When I did expanding with bell ,the case is like on included picture. The plug cut small amount of brass inside and make bulge on the case.

Have you any experience with this?

Thanks.

Jakub.

somewhere here on this forum I read about expander plug. I let make one, with diameter .313 and lenth of the plug is set to calibrate inside of the case to same distance where bullet goes. I am using .314 HN wadcutters. When I did expanding with bell ,the case is like on included picture. The plug cut small amount of brass inside and make bulge on the case.

Have you any experience with this?

Thanks.

Jakub.