IZh35M going full-auto..

Moderators: pilkguns, m1963, David Levene, Spencer, Richard H

Forum rules

If you wish to make a donation to this forum's operation , it would be greatly appreciated.

https://www.paypal.com/paypalme/targettalk?yours=true

If you wish to make a donation to this forum's operation , it would be greatly appreciated.

https://www.paypal.com/paypalme/targettalk?yours=true

IZh35M going full-auto..

I have a almost new IZH35M which I picked up second-hand a few years ago.

It used to misbehave with every sort of .22 ammunition by machine-gunning - no doubt that being the reason for sale and just about brand new condition.

I've been taking off the faintest trace of metal from the breech face by using this - https://www.brownells.com/gunsmith-tool ... od797.aspx

It now works flawlessly with CCI STD .22 and Geco .22 , but still machine-guns with Federal Champion 714 .22.

Why would this happen - and what's the difference between Federal and CCI/Geco?

Do I continue shaving the breech face or not?

What do you guys think?

It used to misbehave with every sort of .22 ammunition by machine-gunning - no doubt that being the reason for sale and just about brand new condition.

I've been taking off the faintest trace of metal from the breech face by using this - https://www.brownells.com/gunsmith-tool ... od797.aspx

It now works flawlessly with CCI STD .22 and Geco .22 , but still machine-guns with Federal Champion 714 .22.

Why would this happen - and what's the difference between Federal and CCI/Geco?

Do I continue shaving the breech face or not?

What do you guys think?

Re: IZh35M going full-auto..

Greetings Leon,

The "Ivans" are not fully heat treated.

My friend had one and it turned out that the headspace on the bolt had been reduced due to firing. When the bolt snapped shut, it compressed the rim of the case enough to discharge it.

My memory is poor; but, I think the solution was to mill the rim recess to meet SAAMI/CIP requirements. I also recall taking a very light cut across the breech of the barrel to clean up any peening that occurred.

The machining tolerances are quite lax on the IZH-35M.

Cheers,

Dave

The "Ivans" are not fully heat treated.

My friend had one and it turned out that the headspace on the bolt had been reduced due to firing. When the bolt snapped shut, it compressed the rim of the case enough to discharge it.

My memory is poor; but, I think the solution was to mill the rim recess to meet SAAMI/CIP requirements. I also recall taking a very light cut across the breech of the barrel to clean up any peening that occurred.

The machining tolerances are quite lax on the IZH-35M.

Cheers,

Dave

Re: IZh35M going full-auto..

Hi Leon,

does it have enough sear engagement?

regards,

Dean

does it have enough sear engagement?

regards,

Dean

Re: IZh35M going full-auto..

Different ammo has priming compound of varying sensitivity, and the brass is different. Softer brass will slam fire easier than harder brass. The rim thickness will also vary. If your headspace is marginal, a thicker rim will cause more issues than a thin one.

I've had to re-headspace a couple of Benelli MP90/95's to prevent slam fires. On those, you can move the barrel forward slightly. Before I worked out how to do that, we found that some pistols would work very reliably with certain ammo, but would slam fire with other brands.

I think Federal ammo tends to be a little easier to fire (intentionally or otherwise) than other brands. I had a MatchGun MG2 that doubled on me from "hammer follow" when the ammo didn't have enough kick to cock the hammer securely. I've had other ammo that couldn't cock the MG2 reliably, but the Federal was the worst, both in terms of not cocking, AND then doubling.

I've had to re-headspace a couple of Benelli MP90/95's to prevent slam fires. On those, you can move the barrel forward slightly. Before I worked out how to do that, we found that some pistols would work very reliably with certain ammo, but would slam fire with other brands.

I think Federal ammo tends to be a little easier to fire (intentionally or otherwise) than other brands. I had a MatchGun MG2 that doubled on me from "hammer follow" when the ammo didn't have enough kick to cock the hammer securely. I've had other ammo that couldn't cock the MG2 reliably, but the Federal was the worst, both in terms of not cocking, AND then doubling.

Re: IZh35M going full-auto..

I wouldn't shave the breechface as that could unnecessarily increase headspace. I'd look for possible peening around the edge of the barrel and checking out the firing pin. Always remove metal of the cheapest, least critical part.Leon wrote: ↑Sun Mar 27, 2022 6:41 pm I have a almost new IZH35M which I picked up second-hand a few years ago.

It used to misbehave with every sort of .22 ammunition by machine-gunning - no doubt that being the reason for sale and just about brand new condition.

I've been taking off the faintest trace of metal from the breech face by using this - https://www.brownells.com/gunsmith-tool ... od797.aspx

It now works flawlessly with CCI STD .22 and Geco .22 , but still machine-guns with Federal Champion 714 .22.

Why would this happen - and what's the difference between Federal and CCI/Geco?

Do I continue shaving the breech face or not?

What do you guys think?

Re: IZh35M going full-auto..

This is a common problem, haven't heard of it on a new gun though.

Typically the breach face above the chamber gets squashed reducing headspace. The slide only contacts the breach face in a small area which recedes and the parts are all soft.

The solution is usually to file back the breach face around the chamber, the cartridge rim also wears a ring into the barrel so it needs to be past that.

Newer models have a catch/bullet guide which slows the slide a bit, some people have drilled a hole in the breach and inserted a piece of plastic eg acetal.

If its ammo dependent likely to be related to ammo sensitivity and rim thickness.

The firing pin has no return spring and could be stuck, not very likely, could be peening or burring somewhere.

The IZH35 has a double sear system and shouldn't go wrong, maybe if its messed with eg by reducing the sear engagement to 'improve' the trigger.

Could still be a manufacturing fault I suppose.

Typically the breach face above the chamber gets squashed reducing headspace. The slide only contacts the breach face in a small area which recedes and the parts are all soft.

The solution is usually to file back the breach face around the chamber, the cartridge rim also wears a ring into the barrel so it needs to be past that.

Newer models have a catch/bullet guide which slows the slide a bit, some people have drilled a hole in the breach and inserted a piece of plastic eg acetal.

If its ammo dependent likely to be related to ammo sensitivity and rim thickness.

The firing pin has no return spring and could be stuck, not very likely, could be peening or burring somewhere.

The IZH35 has a double sear system and shouldn't go wrong, maybe if its messed with eg by reducing the sear engagement to 'improve' the trigger.

Could still be a manufacturing fault I suppose.

Re: IZh35M going full-auto..

Have you considered the possibility you bought an actual submachinegun which your breech-face modification has caused to malfunction with CCI STD .22 and Geco .22?

Re: IZh35M going full-auto..

Haha - in that case I'll advertise on Gunbroker as a Class 3 item, with the appropriate stratospheric price tag !

Re: IZh35M going full-auto..

Have been examining the problem child IZH35M very closely. Where they have mated the barrel to the breech , there is a slight protuberance of a section of barrel outside the breechblock - i.e. looking from the side, it is not completely flush.

This, I think, may be the culprit..

This, I think, may be the culprit..

Re: IZh35M going full-auto..

That would do it, manufacturing defect or the section above the barrel tends to recede with wear.

You can file/mill back the barrel, rechamber a bit deeper with a recess for the rim or extend the breach face eg with an acetal plug.

You can file/mill back the barrel, rechamber a bit deeper with a recess for the rim or extend the breach face eg with an acetal plug.

- crankythunder

- Posts: 255

- Joined: Tue Dec 22, 2009 6:57 pm

- Location: The ugly side of Hell, Michigan

- Contact:

Re: IZh35M going full-auto..

Dear Leon:

I had a IZH 35M that developed that problem and the solution was to get a reverse mill, that is you thread a mandrel through the barrel, attach the reverse mill to the mandrel and as you pull it from the barrel end, it cuts a shallow recess in the breachface the same diameter as a 22LR rim.

By cutting this recess it created enough headspace such that the firearm would function again.

Unfortunately, with the soft metals used in the IZH 35m, the breachface would deform again and this procedure had to be repeated.

I had a couple of 35M's and on one of them I I had removed so much of the breachface that I had to remove additional material from the front of the slide so that it would be positioned correctly in Battery. To give you an idea of how long this will take, i purchased the pistol used and figure that I had four or five cases of ammo through it (20,000 to 25,000 rounds).

I ended up giving that pistol away for parts to a fellow shooter. would not want to sell that headache to a fellow shooter.

While I enjoyed shooting that IZH 35m, I would not purchase one now and would recommend that shooters consider other firearms. the soft metal used simply will not stand up to the intended use of the pistol.

Regards,

Crankster

I had a IZH 35M that developed that problem and the solution was to get a reverse mill, that is you thread a mandrel through the barrel, attach the reverse mill to the mandrel and as you pull it from the barrel end, it cuts a shallow recess in the breachface the same diameter as a 22LR rim.

By cutting this recess it created enough headspace such that the firearm would function again.

Unfortunately, with the soft metals used in the IZH 35m, the breachface would deform again and this procedure had to be repeated.

I had a couple of 35M's and on one of them I I had removed so much of the breachface that I had to remove additional material from the front of the slide so that it would be positioned correctly in Battery. To give you an idea of how long this will take, i purchased the pistol used and figure that I had four or five cases of ammo through it (20,000 to 25,000 rounds).

I ended up giving that pistol away for parts to a fellow shooter. would not want to sell that headache to a fellow shooter.

While I enjoyed shooting that IZH 35m, I would not purchase one now and would recommend that shooters consider other firearms. the soft metal used simply will not stand up to the intended use of the pistol.

Regards,

Crankster

Re: IZh35M going full-auto..

If you never clean them the crud stops the parts slamming together.

Or insert an acetal plug as above and replace it occasionally, easier than machining until there's nothing left and protects the slide.

The MP 438 has a tab which may slow it a bit, I can't find a picture.

Or insert an acetal plug as above and replace it occasionally, easier than machining until there's nothing left and protects the slide.

The MP 438 has a tab which may slow it a bit, I can't find a picture.

Re: IZh35M going full-auto..

"The MP 438 has a tab which may slow it a bit, I can't find a picture."

Hmmm - I had a MP438 and don't recall seeing anything like that.. I'll ask the current owner to have a look.. Meanwhile, my KhR30 has 100% flawless operation...

The only reason I'm persevering with my IZH35M is that I have quite a few spare parts for it - obtained from Alex Taransky.

I bought my IZh35M second-hand and it was like brand new, both internally and externally.

My guess is that it misbehaved straight from the start and the previous owner decided that they didn't really want a machine-gun so it languished in their safe for quite a few years - before deciding to sell it ( to some unsuspecting fool = me ! )

Hmmm - I had a MP438 and don't recall seeing anything like that.. I'll ask the current owner to have a look.. Meanwhile, my KhR30 has 100% flawless operation...

The only reason I'm persevering with my IZH35M is that I have quite a few spare parts for it - obtained from Alex Taransky.

I bought my IZh35M second-hand and it was like brand new, both internally and externally.

My guess is that it misbehaved straight from the start and the previous owner decided that they didn't really want a machine-gun so it languished in their safe for quite a few years - before deciding to sell it ( to some unsuspecting fool = me ! )

Re: IZh35M going full-auto..

I think you can see it here

https://www.rstradehouse.com/item?id=100210134512&l=id

Guns I've seen have a spring loaded tab to stop the round going above the chamber, it also slows the slide a little.

Last time I spoke to him a gunsmith in SA was trying to get rid of an MP438

https://www.rstradehouse.com/item?id=100210134512&l=id

Guns I've seen have a spring loaded tab to stop the round going above the chamber, it also slows the slide a little.

Last time I spoke to him a gunsmith in SA was trying to get rid of an MP438

Re: IZh35M going full-auto..

Last time I spoke to him a gunsmith in SA was trying to get rid of an MP438

Maybe you should pick it up James?

Maybe you should pick it up James?

Re: IZh35M going full-auto..

The tab is attached to a hinged, shaped bar which serves two functions: when the tab (actually a spike) is up it introduces a slide stop at the rear of the "bar" (first pic); when down (with the slide back) the shaped part at the front of the "bar" helps guide the next round into the chamber rather than allowing it to tilt up and hit the breech, as JamesH mentioned.

Bob

Re: IZh35M going full-auto..

As the slide goes forward I think the slide has to lift it out of the way, then it drags on the top.

How significant this is in reducing slide impact on the breach face I don't know.

How significant this is in reducing slide impact on the breach face I don't know.

Re: IZh35M going full-auto..

Better pic of the shaped bar/slide stop. Top IZH-35M, bottom MP-438.

Bob

Bob

Re: IZh35M going full-auto..

I know this thread is older, but I thought I’d add what I did to cure the doubling problem.

Tzed250 wrote: ↑Mon May 17, 2010 6:29 pmThis is a post I made almost two years ago. I hadn't been able to shoot much since then, but now range access and a group to shoot with has become available.Tzed250 wrote:My IZH had a habbit of doubling every once in a while. It doubled consistently with Federal 711B. After reading several articles on the subject, I decided to examine the gun. I stripped the pistol and used a 10X Coddinton magnifier to check the bolt face. Sure enough, it had quite a bit of peening. A few careful minutes with an X-acto knife and a stone removed the burrs. I took it to the range and fired about 200 rounds. No doubling, but there were two failures to eject. I blamed this on chilly temps (about 55 deg.). Another trip to the range, this time with temps in the mid 70s, showed perfect functioning. I will report more when the pistol has more rounds through it.

As soon as I started to put more rounds through my IZH the doubling problem returned. I tried adjusting the trigger, cleaning, different ammo, and even the O-ring buffer in an attempt to make the pistol reliable. No go.

I then measured the headspace for the cartridge rim on the bolt. It measured .040". This was done by using a 1" micrometer across the top and bottom of the bolt face. I knew this was insufficient. The problem is getting a tool to the bolt face to cut the recess for the rim. I ended up finding an old .5" reamer. I cut the fluted section from the tool, then chucked the body in a lathe where I drilled and reamed a .375 bore to hold a 17/64 (.266) four-flute center-cutting end-mill. The .5" reamer was a MT1 mount, so with a MT1-MT2 adapter I was able to mount it in my drill press.

This tool length gave me the ability to reach the bolt face while clearing the rest of the bolt.

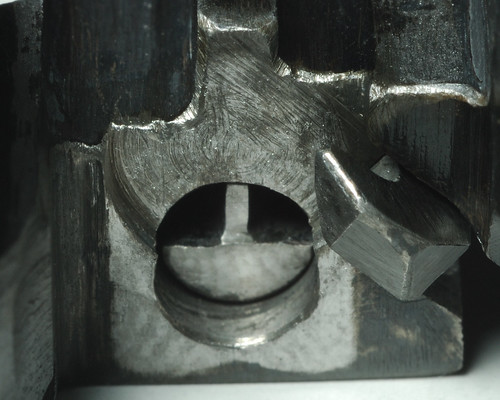

The end-mill is shown here:

The following pictures show the bolt face after machining. The headspace was increased to .046". The firing pin is shown in the ready and fire positions.

On Sunday I went to the range and fired a mix of Remington Subsonic, Remington 22 Target, and Eley Sport, all ammo that had doubled in the pistol previously.

After 300 rounds of slow and rapid fire the pistol did not double one time.

I hope that this has put the reliability of the IZH where it should be, and I will monitor the headspace to ensure it does not enter back into the danger zone.

Questions and comments are welcome.

John.

.