Friendly advice to new people: ball joint allen wrenches

Moderators: pilkguns, m1963, David Levene, Spencer, Richard H

Forum rules

If you wish to make a donation to this forum's operation , it would be greatly appreciated.

https://www.paypal.com/paypalme/targettalk?yours=true

If you wish to make a donation to this forum's operation , it would be greatly appreciated.

https://www.paypal.com/paypalme/targettalk?yours=true

Friendly advice to new people: ball joint allen wrenches

So I've noticed that we've gotten a fair number of new shooters recently (myself included) and just wanted to share a tip I just figured out about:

Buy a full set of Allen wrenches with a ball end in metric sizes, stainless steel preferrably. They're much longer (more torque) and the ball end lets you screw things in at a slight angle (those small wrenches are a bit fiddly and I lost at least one before because I couldn't keep the darn thing in the screw...), making dropping the wrenches much less likely. The stainless steel will make it easier to find if it DOES drop.

It's about $20 and will make your experiences with the gun much less aggravating. Happy shooting!

Buy a full set of Allen wrenches with a ball end in metric sizes, stainless steel preferrably. They're much longer (more torque) and the ball end lets you screw things in at a slight angle (those small wrenches are a bit fiddly and I lost at least one before because I couldn't keep the darn thing in the screw...), making dropping the wrenches much less likely. The stainless steel will make it easier to find if it DOES drop.

It's about $20 and will make your experiences with the gun much less aggravating. Happy shooting!

-

TenMetrePeter

- Posts: 603

- Joined: Sun Sep 04, 2016 10:59 am

Re: Friendly advice to new people: ball joint allen wrenches

Agree, and that's a good amount to pay for Allen keys. So many sets sold at a couple of pounds/dollars don't even have consistent sizing. Our 99pence store sold allen keys that could be bent by hand (yes I tried it).

I would caution about torque. The longer leverage is great for UNdoing, but re-tightening should be done carefully. There are very few screws on an air weapon that need any more than the torque provided by holding the short end of the key in the hand with the long end in the screw, and only finished off with a 1/8th turn tweak using the long leverage.

I have never owned a torque wrench for allen keys - I reserved torque wrenches for engine cylinder heads and wheel nuts only! Maybe if I owned a firearm that needed bedding into the stock properly I would invest in one.

I would caution about torque. The longer leverage is great for UNdoing, but re-tightening should be done carefully. There are very few screws on an air weapon that need any more than the torque provided by holding the short end of the key in the hand with the long end in the screw, and only finished off with a 1/8th turn tweak using the long leverage.

I have never owned a torque wrench for allen keys - I reserved torque wrenches for engine cylinder heads and wheel nuts only! Maybe if I owned a firearm that needed bedding into the stock properly I would invest in one.

Re: Friendly advice to new people: ball joint allen wrenches

If you have trouble dropping things, don't do your gunsmithing on the throne.

Re: Friendly advice to new people: ball joint allen wrenches

Great points. Never overtighten a pistol screw, obviously. Also, I was using torque in the sense of just turning the screws with your hands (if you are using a torque wrench on a gun you are either assembling it for the first time or you are doing it something wrong). Sometimes those screws can be stuck on by the factory a bit hard, but should never be tightened back hard unless you fancy stripped screws and professional repair bills.TenMetrePeter wrote:Agree, and that's a good amount to pay for Allen keys. So many sets sold at a couple of pounds/dollars don't even have consistent sizing. Our 99pence store sold allen keys that could be bent by hand (yes I tried it).

I would caution about torque. The longer leverage is great for UNdoing, but re-tightening should be done carefully. There are very few screws on an air weapon that need any more than the torque provided by holding the short end of the key in the hand with the long end in the screw, and only finished off with a 1/8th turn tweak using the long leverage.

I have never owned a torque wrench for allen keys - I reserved torque wrenches for engine cylinder heads and wheel nuts only! Maybe if I owned a firearm that needed bedding into the stock properly I would invest in one.

Re: Friendly advice to new people: ball joint allen wrenches

Crappy situations may occur, 'tis true. I refer you to Robert Service's "The Three Bares" for more on the subtle interactions between man, chamber pot and tools.Rover wrote:If you have trouble dropping things, don't do your gunsmithing on the throne.

Re: Friendly advice to new people: ball joint allen wrenches

Why are stainless steel allen wrenches easier to find if you drop them, over ordinary ones?

I was always taught you do not torque anything with the ball end, because the hex surface area is severely reduced. Also if some really needs torqing (as compared to tightening) then use good qualit, heat treated steel hx wrenches.

Note of caution: Stainless steel fasteners on guns are neat because they do not rust, and look neat. However they are NOT strong. Many a small bolt has been stripped or simply twisted in two.

I was always taught you do not torque anything with the ball end, because the hex surface area is severely reduced. Also if some really needs torqing (as compared to tightening) then use good qualit, heat treated steel hx wrenches.

Note of caution: Stainless steel fasteners on guns are neat because they do not rust, and look neat. However they are NOT strong. Many a small bolt has been stripped or simply twisted in two.

Re: Friendly advice to new people: ball joint allen wrenches

In the US, McMaster Carr sells "gold" ball end metric keys. I suspect they are titanium nitride coated, and are very visible when dropped or buried on a bench.

For serious gunsmithing, they also have "extra strength" hex keys, which are good for removing screws with threadlocker on them. If someone used high strength threadlocker, you can break even those keys unless you heat the screw first. A 700F soldering iron tip stuck in the hex socket for 15-20 minutes does the trick.

For serious gunsmithing, they also have "extra strength" hex keys, which are good for removing screws with threadlocker on them. If someone used high strength threadlocker, you can break even those keys unless you heat the screw first. A 700F soldering iron tip stuck in the hex socket for 15-20 minutes does the trick.

Re: Friendly advice to new people: ball joint allen wrenches

Wiha is a great source for t-handle hex and wing torx tools. They are much harder to lose. Also, they are properly heat treated for long life. Wiha USA has a different sale, almost every month:

https://www.wihatools.com/hex-t-handle- ... -piece-set

https://www.wihatools.com/soft-grip-dua ... -piece-set

https://www.wihatools.com/hex-t-handle- ... -piece-set

https://www.wihatools.com/soft-grip-dua ... -piece-set

Re: Friendly advice to new people: ball joint allen wrenches

This is for people without a dedicated workspace (those allen keys are easy as hell to lose in a couch). The stainless ones are (1) longer and (2) shinier than the ones provided with the gun.Pheyden wrote:Why are stainless steel allen wrenches easier to find if you drop them, over ordinary ones?

[. . . .]

Note of caution: Stainless steel fasteners on guns are neat because they do not rust, and look neat. However they are NOT strong. Many a small bolt has been stripped or simply twisted in two.

Second part: I agree with you 100%. I'm aiming this at people who need to adjust sights, not take the gun apart. If I was going to be taking down my steyr for more serious work, I'd use heat-treated steel. But for those of us who are just starting out and just need to fiddle with the adjustment screws, stainless steel presents an economical alternative with some nice advantages.

-

jaxontarget

- Posts: 157

- Joined: Mon Nov 07, 2016 9:09 pm

Re: Friendly advice to new people: ball joint allen wrenches

I'll second the thumbs up for Wiha tools. PB Swiss also makes a great set that are color coded, which helps if you're using multiples in close sizes. As a bonus they'll stand out more for retrieval should you ignore Rovers advice and drop them in the toilet.

-

Linecutter

- Posts: 15

- Joined: Wed Aug 29, 2012 5:46 pm

Re: Friendly advice to new people: ball joint allen wrenches

Surely after 15-20 minutes the whole gun will start to get warm?Gwhite wrote:A 700F soldering iron tip stuck in the hex socket for 15-20 minutes does the trick.

Re: Friendly advice to new people: ball joint allen wrenches

Harbor Freight makes T-handle wrenches and they're decent, but nothing beats Bondhus or Wiha

Re: Friendly advice to new people: ball joint allen wrenches

The thermal conduction from the soldering iron tip to the screw is pretty poor, and the threadlocker isn't a great thermal conductor. You need to get the threadlocker up to at least ~ 300F before it softens significantly. The rest of the pistol will be warm, and the area right around the screw will be too hot to touch. Gloves are a good idea to hang onto the assembly with the screw stuck in it.Linecutter wrote:Surely after 15-20 minutes the whole gun will start to get warm?Gwhite wrote:A 700F soldering iron tip stuck in the hex socket for 15-20 minutes does the trick.

I try to sneak up on it, trying the screw occasionally until it lets go. The screws should not be re-used, because the temperatures are high enough to wreck whatever heat treating they had. It's a good idea to have a spare key key or two handy, in case you snap one before the screws let go.

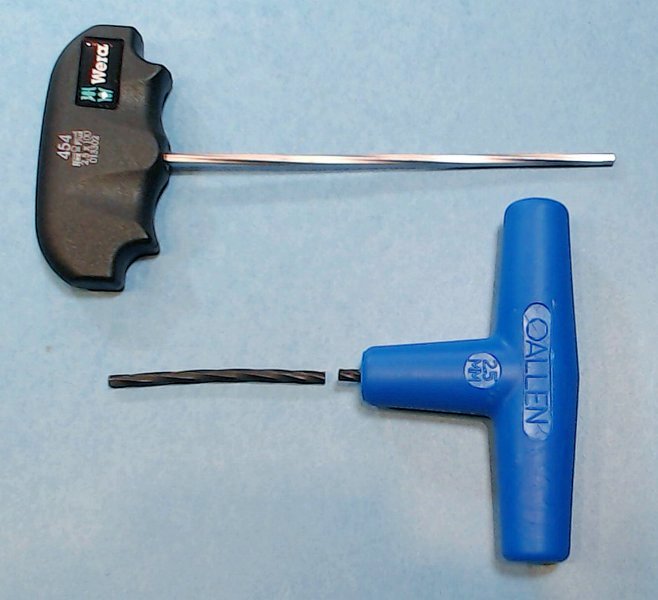

The top one is a "high strength" hex key, and it did the trick. It is not ordinarily spiraled like that... The bottom one is a regular key that failed before i got a screw hot enough.

Re: Friendly advice to new people: ball joint allen wrenches

Good luck finding one small enough to be useful without destroying things. The screws I was dealing with used a 2.5mm hex key. Nobody I know of makes impact rated bits anywhere near that small. I tried some short bits with a high torque Tee handle, and snapped the ends right off.SamEEE wrote:A rattlegun will do it.

Re: Friendly advice to new people: ball joint allen wrenches

You know I've gotten some crap on the forum for speaking in legalese.

I think I'm starting to understand what it feels like to listen to that because I have absolutely no clue what you folks are talking about now...why would I even own a soldering iron...?

I think I'm starting to understand what it feels like to listen to that because I have absolutely no clue what you folks are talking about now...why would I even own a soldering iron...?

Re: Friendly advice to new people: ball joint allen wrenches

Gwhite wrote:Good luck finding one small enough to be useful without destroying things. The screws I was dealing with used a 2.5mm hex key. Nobody I know of makes impact rated bits anywhere near that small. I tried some short bits with a high torque Tee handle, and snapped the ends right off.SamEEE wrote:A rattlegun will do it.

1" inch drive, with lots and lots of step-down adapters. :D

Chia wrote:..why would I even own a soldering iron...?

To make solder joints! A hot nail will work for the odd job, otherwise this chi-com Haako knockoff is pretty good for the money. Pretty hard to go wrong for 20 bucks and will take genuine haako tips.

https://hobbyking.com/en_us/soldering-s ... house.html

-

TenMetrePeter

- Posts: 603

- Joined: Sun Sep 04, 2016 10:59 am

Re: Friendly advice to new people: ball joint allen wrenches

I bought my first soldering iron at the age of 11 which was more than half a century ago. If you are a constructor or "mendologist" it's essential kit. If the 9v connector pulls off the wires inside the radio or the grand kids' fire engine stops hooting, there are those who will fix it and those who will go and buy another. They do still make things where the back comes off to fix it but maybe not for much longer.Chia wrote:You know I've gotten some crap on the forum for speaking in legalese.

I think I'm starting to understand what it feels like to listen to that because I have absolutely no clue what you folks are talking about now...why would I even own a soldering iron...?

My son the lawyer wouldn't have a use for one either - mainly because I fix everything.!

Re: Friendly advice to new people: ball joint allen wrenches

One of the things about pistols is that they are (usually) worth fixing. That provides an excuse to learn new skills (and buy new tools).

If an Olympic grade air pistol cost $20 and could be delivered by Amazon the next day, I probably wouldn't bother...

If an Olympic grade air pistol cost $20 and could be delivered by Amazon the next day, I probably wouldn't bother...

- SlartyBartFast

- Posts: 579

- Joined: Fri Jun 10, 2016 11:04 am

- Location: Montreal, Québec, Canada

Re: Friendly advice to new people: ball joint allen wrenches

Here you go, impact bit down to 1.5 mm.Gwhite wrote:Good luck finding one small enough to be useful without destroying things. The screws I was dealing with used a 2.5mm hex key. Nobody I know of makes impact rated bits anywhere near that small. I tried some short bits with a high torque Tee handle, and snapped the ends right off.

http://www.princessauto.com/en/detail/1 ... -p8573362e

I bought an impact bit set from Canadian Tire for the takedown screw on my SW22 Victory.

- Smith & Wesson SW22 Victory

- FAS SP607

- FAS SP607